Let’s get to know Reis Standing Seam Technologies…

|

|

We entered the standing seam roof industry with sales and service of the machines and equipment needed for the metal roof application, especially the standing seam roof machine, seamer and Roofing tools, for about 20 years ago.

We have served the industry for many years as the Turkiye Distributor of many European manufacturers ( schlebach, Schechtl, Biegemaster, Wuko, Rau, Freund, Biegetec, Buschmann etc.)

Today, the Turkiye dealership of many of these brands is still continues successfully by Company KARACE.

We started our work in 2020 and opened our production workshop under the name of “Reis Standing Seam Technologies” to show that standing seam roofers can have a portable standing seam machine of high quality but at an affordable price.

The increasing demand from roofers for the “R-PRO 25” standing seam machine, which produces high-precision standing seam metal with no length limit, has been an important source of motivation for us.

As Reis Standing Seam Technologies, what we care most about is sustainable quality and trust. We have a dedicated and highly experienced team from our establishment until today. That’s why we have strong and positive communication with roofers all over the world and especially with our sales partner in different countries.

In addition to our leadership in standing seam Technologies in Turkiye, the orders and customer satisfaction for the “R-PRO 25” Standing Seam Roof Machine from many countries around the world make us very happy.

Price and Performance – Right Choice

“R-PRO 25” Portable Roof Standing Seam Machine…

When it comes to standing seam machine,

3 options available:

First one: Big, hard to carry, expensive metal roof standing seam machines,

Second one; Cheap but unreliable standing seam machines,

Third one; High performance “R-PRO 25” Standing Seam Machine at affordable price.

We produced the “R-PRO 25” portable roll form model so that roofers can have maximum mobility with a low-cost standing seam machine.

We are spreading around the world…

You may encounter standing seam roofs produced with our profiling machines in the different parts of the world.

From Türkiye to Germany

To USA, India…

To Canada, Italy…

To France, Georgia…

To Netherlands, Bulgaria…

Croatia, Serbia…

“R-PRO 25” Portable Standing Seam Machines are working in over 30 countries.

We eliminate the distances!

The transportation of “R-PRO 25” Standing Seam Machine is very safe. It is shipped with closed cage pallet. So the machine is protected during delivery. Shipped safely from the nearest countries to the longest distances.

Delivery times of transportation agents are very short. It reaches European countries within 2-3 days, and countries such as USA and Canada within 15-20 days.

Dedication and Expertise – Sales and After-sales Service…

We are always there for our customers with our stocked spare parts, from production to assembly, from sales to technical service.

We have a dynamic and experienced technical service team. We respond very quickly to any request. Spare parts of “R-PRO 25” Standing Seam Machine are always available on our stock. In case of need, we deliverthe spare parts immediately by airfreight.

It is very easy to use “R-PRO 25” Standing Seam Profiling Machine. It definitely does not have a complicated structure. It can start working immediately after you recieve it.

There is always an English user manual with the roof standing seam machine. User manuals are also available for different languages. There is also a practical, easy-to-explain English video available. This video will be sent immediately after the standing seam machine is shipped.

We give you the support you need while using the standing seam machine live, directly on the machina via video call. Other option; you can show us the problem by taking videos and photos. Then we take photos and videos showing what needs to be done on the machine in our factory and send them to you. It’s all that simple!

The “R-PRO 25” Standing Seam Machine is very easy to use and maintain and has a 2 year warranty.

Production of Standing Seam Panels with “R-PRO 25”…

We have adopted the principle of creating technological and economic solutions throughout our development.

As a result of our R&D studies, we have become a brand that brings our products together with roofers after completing the production and tests from the design stage.

Every manufactured “R-PRO 25” standing seam machine goes through delicate tests and controls. Machines have CE and EU Attestation of Compliance Cerftificate.

With the user-friendly, powerful and robust “R-PRO 25” standing seam machine, you can perform your standing seam roof applications in a quality-oriented manner.

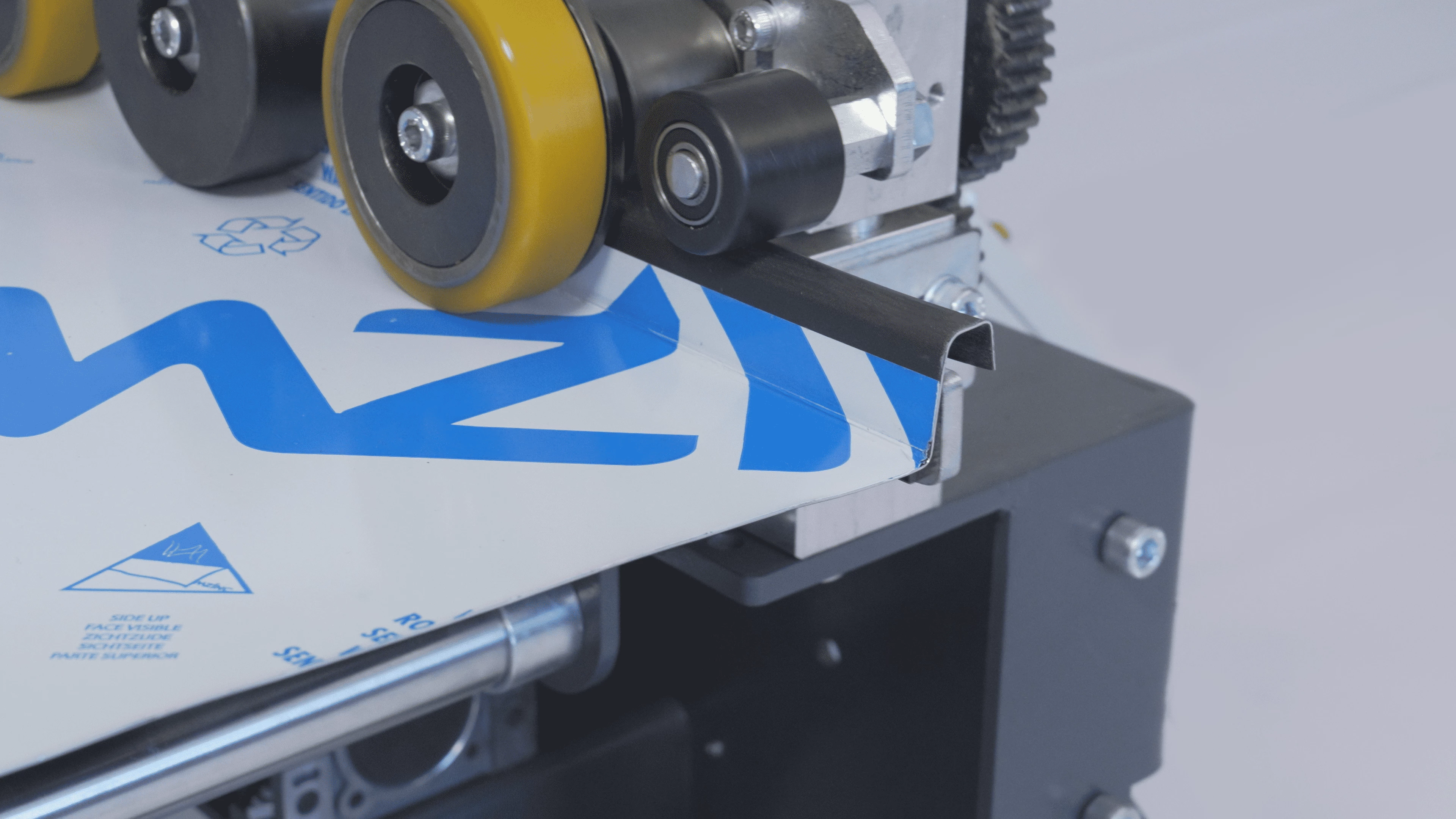

You can work with different kind of materials and produce high quality roof panels. It’s a proven model in standing seam metal production.

You can give high quality form to all metals produced in internationally valid norms such as Vmzinc Titanium Zinc, Rheinzink Titanium Zinc, Elzinc Titanium Zinc, Nedzink Titanium zinc, Zintek Titanium zinc, Silesia Titanium Zinc, Vestis Aluminium, Novelis Aluminium, Latem Aluminium, Prefa Aluminium, Kme Copper, Aurubis Copper, Colorbond Steel, Greencoat Steel, Lindab Steel, Roofinox etc.

Material thickness information is as follows:

Titanium zinc up to 0.8 mm

Copper up to 0.8 mm

Aluminium up to 0.8 mm

Sheet steel (galvanized and coated) up to 0.7 mm

Stainless steel up to 0.5 mm

Compact, light weight, easily portable and many more features…

“R-PRO 25” Standing seam roof machine consists of 4 parts. It can be disassembled and installed in a short period of time, if necessary. Can be carried by two people in disassembled form.

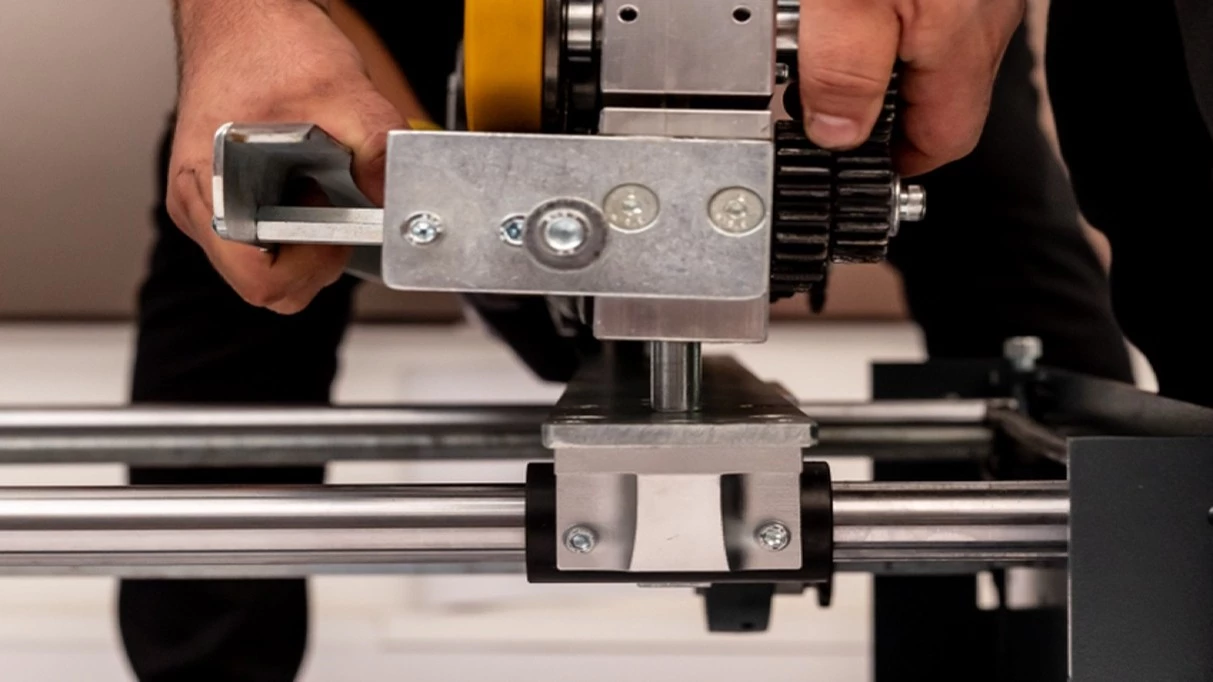

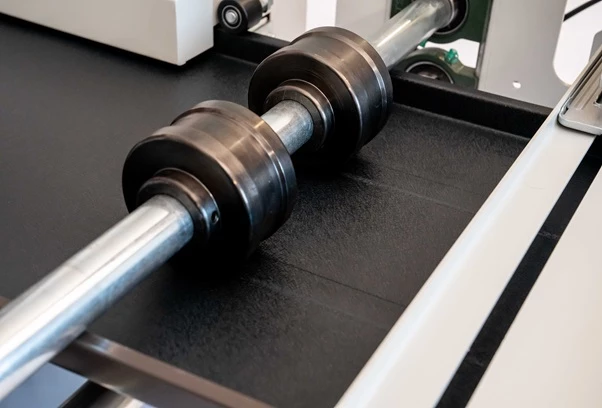

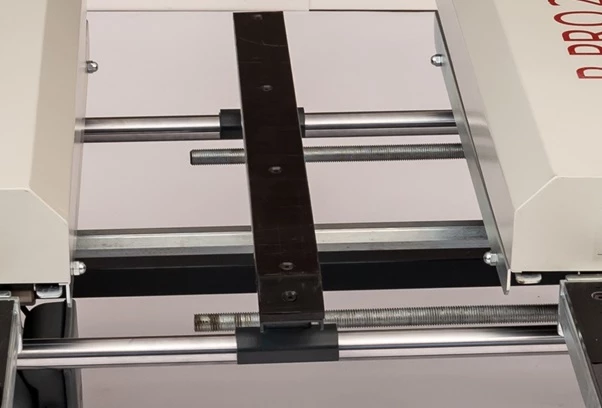

Standing seam panels are produced in high quality, thanks to the use of 7 sets of optimized roll forming roller designs.

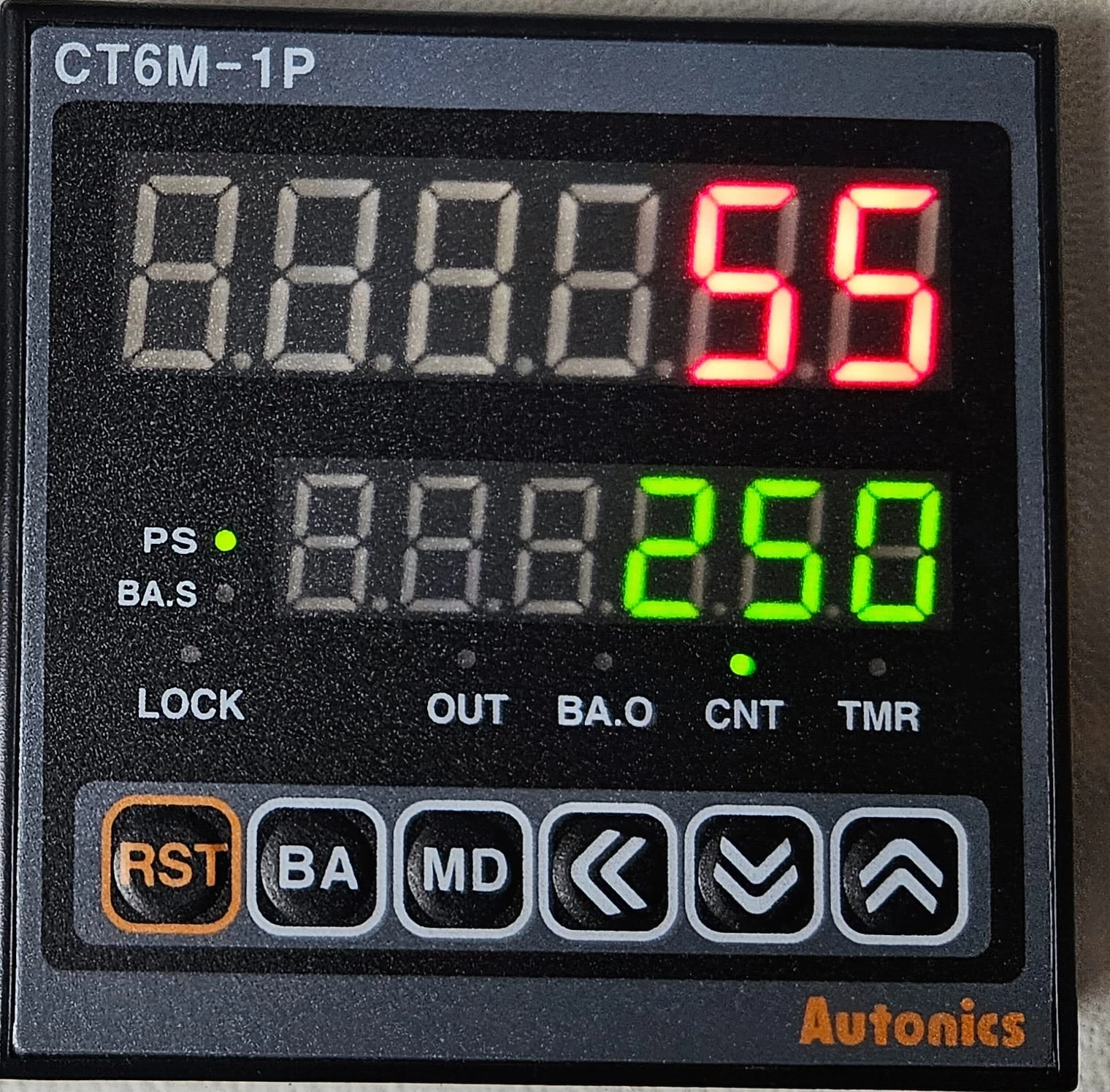

Digital Conrol unit with special memory for easy entry of length measurement and quantities. When the desired length is entered on the screen, the machine stops automatically when it reaches it. The same process repeats until new measurements are entered on the digital screen.

Making 25 mm wide – 1,1 mm deep longitudinal strip marks on the panel with optional ribbing attachment device. This feature is preffered to increase aesthetic appearance or material strength.

Easy working around the machine thanks to the remote control with extension cable. Thus, there is no need to walk around the machine and turn it on and off every time. Additionally, the emergency stop button can be activated from the remote control.

Reverse function and emergency stop. If it is necessary to intervene in the material inside the machine for different reasons, the material can be discharged from the machine thanks to the reverse working feature.

Material fix, support base; It is a useful equipment to ensure that the material inside the machine moves smoothly.

Detachable infeed arms; It is a system that can be easily disassembled and installed so that the machine does not get damaged and does not take up too much space when moving to a different place.

|

|

“R-PRO 25” Standing seam roof machine is a really compact model.

Length: 1200 mm / Width: 900 mm / Height: 580 mm

With lockable wheels and it weighs 190 kg

Therefore, it can be easily transported by all kinds of vans and station wagons. It is suitable for all hard-to-reach jobsites and finds a place in the smallest workshops.

|

|

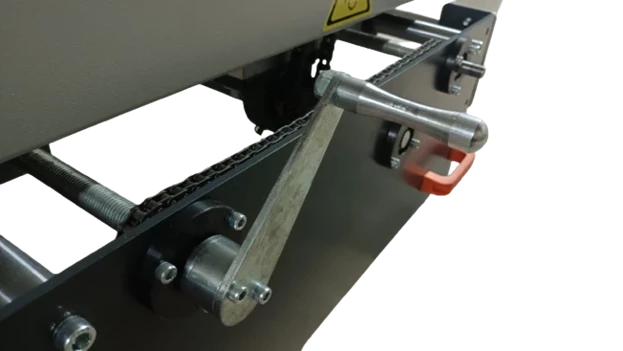

2 different types of cutting device: Guillotine Shear or circular saw cutting may be preffered, attached at the exit of the machine. Having the cutting device at the machine exit ensures waste-free cutting from the length of the material and prevents loss of time.

With the easy rotation of the crank, material width adjustment can be made quickly to the desired size within the range of 250 – 700 mm.

“R-PRO 25” Roof profiling machine produces 25 mm high standing seam panels in a single pass from coils or sheets.

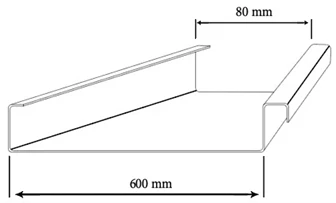

It can also produce standing seam panels from conical sheets. The operation can be made in two operations from conical sheets. The smallest axial dimension is 80 mm with single-sided standing seam production.

Axial width dimension: 170 – 620 mm

( depends on material type )

DEMOUNTED “R-PRO 25” STANDING SEAM PROFILING MACHINE