R-Pro 25

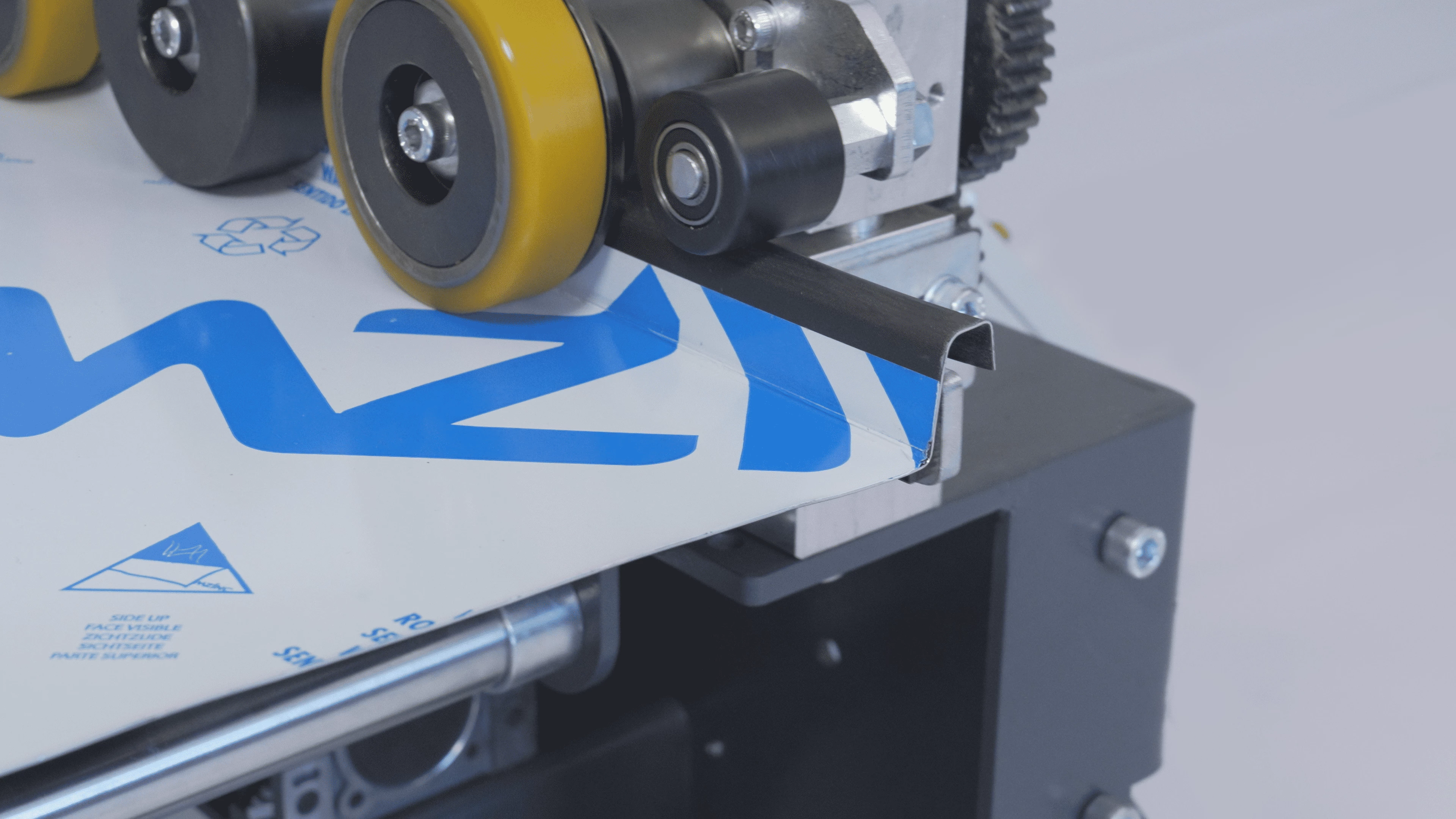

Standing Seam Metal Profiling Machine

You can perform your Standing seam roof applications in a quality-oriented manner with “R-PRO 25” Standing Seam Profiling Machine.

Machine is designed to provide roofers maximum mobility at low cost.

It is a model produced with the highest precision on CNC Processing Machines.

The basic model “R-PRO 25” is a very light and compact Standing seam roof profiling machine that can easily be carried to anywhere.

Metal roof profiling machine that you can work with trouble-free for years with its easy use, high performance, efficiency and durability.

High precision Standing seam panel production is possible without any length limit.

![]()

As REIS STANDING SEAM TECHNOLOGIES, we always support our customers with spare parts on stock, from production to assemble, from sales to techical service.

![]()

Every manufactured “R-PRO 25” Standing Seam Machine goes through delicate tests. It has CE Certificate and EU Attestation of Compliance Certificate.

![]()

You can work with different kind of metals and produce high quality Standing seam roof panels.

![]()

You can produce Standing seam profiles using painted steel, aluminum, titanium zinc, copper or stainless steel.

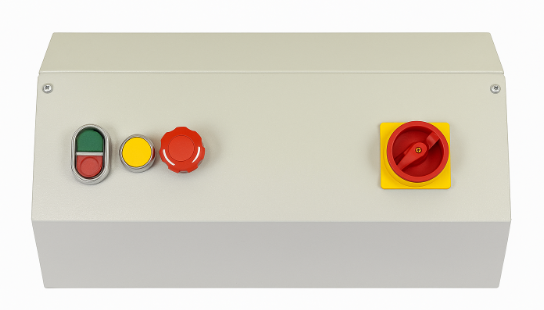

EQUIPMENTS

"R-PRO 25"

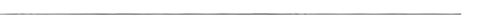

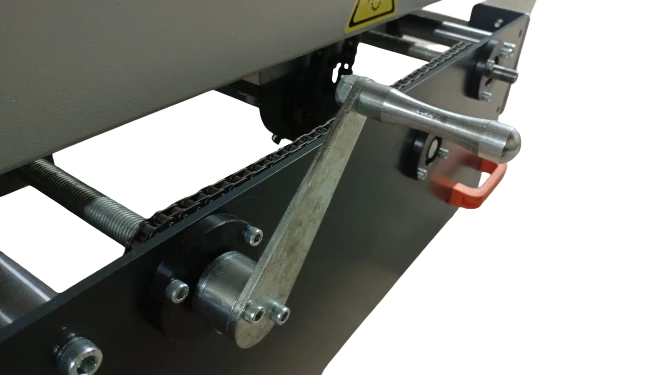

Perfect Standing seam profile production with 25 mm seam height is achieved in a single pass from coil or sheet.

Standing seam profiles can also be produced from conical sheets. The minimum axial dimansion 80 mm with single-sided seam production.

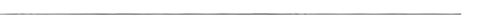

Easy working around the machine thanks to the remote control with the extension cable

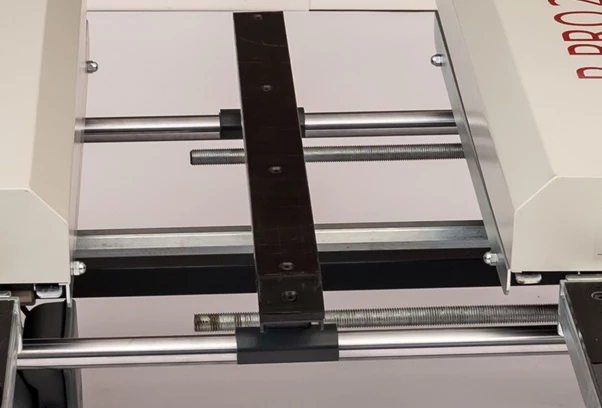

“R-PRO 25” Standing Seam roof machine consists of 3 parts. It can be disassembled and installed in a short period of time, if necessary.

“R-PRO 25” Standing seam machine is suitable for all hard-to-reach jobsites and finds a place in the smallest workshops.

Standing seam panels are produced in high quality, thanks to the use of 7 sets of optimized roll forming roller designs.

“R-PRO 25” Standing seam roll former can be easily transported by all kinds of panel vans and station wagons.

Detechable infeed arms

Reverse function and emergency stop

Material fix, support base

With the easy rotation of the crank, material width adjustment can be made quickly to the desired size within the range of 250 – 700 mm

QUALITY and TRUST

REIS STANDING SEAM TECHNOLIGIES

- Every manufactured “R-PRO 25” standing seam machine goes through delicate tests

- Easy maintenance

- CE Certificate

- EU Attestation of Compliance Certificate

- 2 years of warranty

- Strong management. Loyal, highly trained team.

|

TECHNICAL FEATURES "R-PRO 25"

|

|